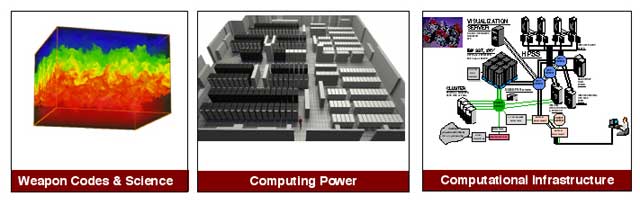

The Advanced Simulation and Computing Program (ASC) is an integral and vital element of our nation's Stockpile Stewardship Program. ASC provides the integrating simulation and modeling capabilities and technologies needed to combine new and old experimental data, past nuclear test data, and past design and engineering experience into a powerful tool for future design assessment and certification of nuclear weapons and their components (see Fig. 1).

ASC simulation and modeling capability supports the Directed Stockpile Work (DSW) program activities by providing capabilities to assess stockpile surveillance significant findings investigations (SFIs) and subsequent decisions regarding the nuclear weapon system and its components. These capabilities are also vital to the stockpile life extension planned activities by providing the simulation and modeling tools needed to certify the performance, safety, and reliability of aging nuclear weapons or weapons that are modified with refurbished components.

ASC capabilities are needed to model prior manufacturing processes for weapon components and define new, cost-effective, safe, and environmentally compliant manufacturing processes that will provide for consistent nuclear weapon performance, safety, and reliability in the future.

ASC simulation and modeling predictive capability relies on a robust experimental program to support the assessment of stockpile issues and provide materials and physics data needed to validate new scientific models and theories being implemented into the simulation codes. These simulations have been, and will continue to be, used to define experimental resolutions and configurations needed for meaningful validation data and to enhance and refine experimental capabilities (see Fig. 2).

The simulation and modeling tools have already made impacts on the assessment of stockpile issues, far in advance of the planned schedules in this program plan. Weapon designers, scientists, and engineers now require ASC simulation and modeling capabilities and technologies to assess aging changes occurring in stockpile nuclear weapons and to assess and certify planned refurbishments of weapon system components.

ASC must maintain a close relationship with both DSW, which contains the Stockpile Life Extension Program (LEP), and the Defense Science Program Campaigns (see Fig. 3). In the ASC-DSW partnership, ASC negotiates requirements with and provides validated capabilities to DSW. ASC in turn must look to the Defense Science Program Campaigns to provide additional science and experimental data to support the development of the validated simulation capability that meets the needs of DSW. ASC will also provide important computational capabilities to support experiment design and to explore revalidation in a simulation environment.

Relationship of ASC to Directed Stockpile Work

The DSW program conducts the surveillance, maintenance, refurbishment, and manufacturing activities for nuclear weapons in the stockpile. This program serves as the principal Defense Programs (DP) interface with the Department of Defense (DoD). DSW is responsible for activities that lead to the continuing assessment of the performance, safety, and reliability of aging nuclear weapons and the certification of weapons that are modified with refurbished components (see Fig. 4). ASC supports the DSW program by providing advanced simulation and modeling capabilities and technologies that lead to high-confidence assessments and certification of the nuclear weapon stockpile consistent with the DSW refurbishment schedule and the discovery of surveillance findings.

ASC simulation and modeling capabilities are currently being used to assess several unresolved surveillance SFIs. Typically, these unresolved investigations concern aging or poor original manufacturing of weapon components. Assessing the impact of current surveillance findings on weapon performance and safety requires three-dimensional simulations, and in some situations, the use of new numerical techniques in the ASC simulation codes that are not available in the legacy codes. However, these simulations cannot currently be carried out with the desired resolution or materials and physics models on the current Blue Mountain, Red, and Blue Pacific platforms because of the processor speed and memory limitations of the platforms. Our estimates indicate we require a factor of 25 increase in both resolution (memory) and speed (teraOPS) to perform these simulations with adequate resolution, and improved materials and physics models in a timely fashion (one to two weeks). New surveillance findings will occur in the future for our aging weapons, and ASC simulation capabilities will be needed for an assessment of the weapon performance, safety and reliability.

Our simulation capabilities will be used to support the W80 and W76 stockpile refurbishment assessment and certification. Engineering analysis capabilities will be used to model high fidelity flight tests for several nuclear weapon systems.

Relationship of ASC to the Defense Science Program (Campaigns)

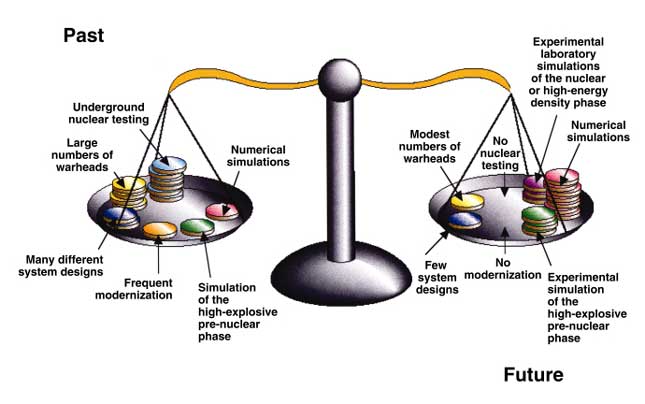

The Defense Science Program is the primary source of science development, testing (including previous underground tests), and experiments needed to manage the U.S. nuclear stockpile. In the previous era of test-based confidence, this program provided direct answers about the performance, safety, and reliability of the stockpile. In the current era without underground testing, with reduced aboveground tests, and with new manufacturing processes, the focus is shifting to computation-based confidence, which requires a strong relationship between ASC and the Defense Science Program (see Fig. 5).

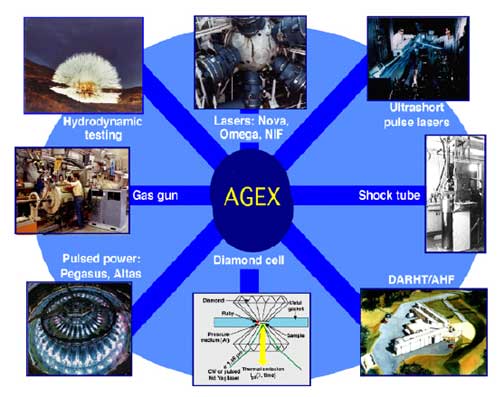

The Campaigns provide the understanding in science and the data for improving physics models needed to understand weapon performance. ASC provides the verified and validated codes, supercomputer platforms, and simulation environment that make it possible to simulate the operation and aging of U.S. weapon systems. Stockpile stewardship will also provide the experimental facilities, like the National Ignition Facility (NIF) and the Dual Axis Hydrodynamic Testing (DARHT) Facility, which will be used to develop new physics models and provide validation data. In addition, the Microsystems and Engineering Sciences Applications (MESA) Facility will provide new engineering design and development capabilities. Finally, the Stockpile Stewardship Program will maintain and continue to develop and understand the archival data from past underground tests, which provide a critical link back to full-scale weapon tests.

Experimental Data Needed by ASC

The ability of ASC to supply validated physics and materials models in the next-generation simulation codes depends on the availability of high-quality, fundamental experimental data for use in our verification and validation efforts. There are several areas of the physics and materials modeling effort where existing data and the current state of the theory and modeling permit the implementation of physics and materials models into the ASC simulation codes and permit the initiation of significant validation efforts. In some of these areas, additional data may be needed to complete the validation, but enough data is in hand to begin the process of validation. The materials and physics models initially implemented do not in all cases represent the ultimate expression of the physics; they are generally significant improvements over models available in the legacy codes. Over time as our computing systems become more capable, additional higher-fidelity models will be implemented. The higher-fidelity physics and materials model implementation will generate additional requirements for validation data (see Fig. 6).

Two principal types of data are required: (1) fundamental data in simplified geometry to validate the physics and materials models without conflicting effects, and (2) integral or system data from larger-scale, more traditional capabilities (e.g., hydrodynamic testing).

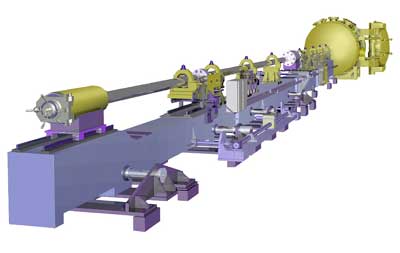

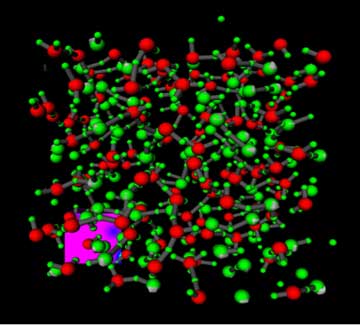

Several sets of existing data have not yet been fully incorporated into the ASC modeling efforts, including data from subcritical experiments and numerous plutonium gas-gun shots. A recent release of a new plutonium equation-of-state table draws from the subcritical experimental data. The gas-gun data is very rich and has just begun to be incorporated, initially as low-pressure equation-of-state data. In the future, the gas-gun data will be incorporated to address related issues of melt, spall, elastic properties, etc. Similar data exists for weapon surrogate materials, and the development work in ASC permits higher-fidelity models for all materials. Some neutron scattering experimental data exist for elastic constants, permitting more accurate potentials for the various elements, including plutonium. Refinements to the equation of state, especially with plutonium, will require additional data in the future. Higher-pressure data will be derived from experiments on the JASPER two-stage gas gun at NTS, which is now in its final qualification phase (see Fig. 7). The details of phase transitions and melt are very important but not well explained by the current models. While an emphasis is placed on plutonium experimental data, several metals in common use in the nuclear weapons also need additional data, including uranium and surrogates of these materials. Proton-radiography and subcritical experiments are being used to provide validation data for modeling ejecta creation and transport.

Past nuclear test data is an important way of assessing details of the explosion phase of a nuclear weapon. A reevaluation and reanalysis of past nuclear test radiochemistry data is under way. The nuclear data evaluations used in both the legacy and the ASC advanced simulation codes are constrained by experimental data. Recently completed measurements of (n,2n) cross section at high energies [U-235(n,2n), U-238(n,2n) and Pu-239(n,2n)] have been incorporated into improved evaluations. Experimental data for other isotopes used in past nuclear tests are also being incorporated into nuclear data evaluations. The new evaluations have changed the interpretation of weapon performance in past nuclear tests.

High-explosive experimental data measuring detonation curvature during burn have been obtained over the past few years for various types of high explosives under different environmental conditions. Improved high explosives models have been developed that are intended to replace the very crude programmed burn treatments used in the past (see Fig. 8).

The Detonation Shock Dynamics model has already been implemented into ASC simulation tools. Experiments such as the embedded gauge shots and interface velocity measurements provide quantitative shock-initiation/reactivity experimental data that are important for our development of physically based reaction models for our next-generation reactive burn treatments. Significant refinement of high explosives equations of state have been made possible through extremely accurate and very elegant plate-push experiments on conventional and insensitive high explosives. Measurements of the multiaxial stress-strain of high explosives (up to failure) have been made to improve our dynamic structural analysis modeling of the stockpile-to-target sequence for weapon systems.

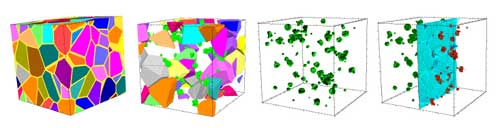

Significant progress has been made in the measurements of fundamental weapons materials properties. Experimental data for grain orientation and texture have been measured to validate the modeling of microstructural phenomena. Resonant ultrasound measurements have provided validation data for the modeling the elastic behavior of weapons materials. Dynamic testing (e.g., split Hopkinson Bar) has provided high-strain and strain-rate experimental data for the validation of materials stress-strain behavior. In addition, flyer-plate experiments provide experimental data needed to validate material damage generation and spall. These data have allowed us to develop models of weapons materials that are significantly better than historical models. Modeling the stockpile-to-target sequence of a weapon system requires low strain-rate-material-behavior models describing the materials dynamic response. Experimental data have been taken that provide validation of significant improvements in crush-up models for several weapons materials to enhance significantly our engineering assessment capabilities (see Fig. 9).

The loss of underground testing has curtailed the ability to perform qualification experiments on components in nuclear radiation environments. Aboveground radiation facilities (SPHINX, SATURN, Z-Machine, Annular Core Research Reactor) provide radiation sources for measurement of material properties and response to develop models for System Generated Electromagnetic Pulse (SGEMP), to study physical phenomena such as radiation-induced conductivity, and for validation of the ASC physical models.

Much of the experimental evidence used to validate instability and mix models is legacy data from rocket-rigs, linear electric motors, shock tubes, pulsed-power machines, and past nuclear tests. More recently, new gas-curtain shock tube and two-stage gas-gun experimental data have been measured to provide validation data for the modeling of Richtmyer-Meshkov instabilities in fluids and solids. Experimental data from laser (Nova, Omega, and Trident) and pulsed power (Z and Atlas) facilities have provided validation data for the modeling of instabilities in plasmas. Experimental data were obtained on the Nova laser that contributed valuable constraints for the development of higher-fidelity opacity tables.

There are numerous examples where the ASC simulation capabilities have made significant contributions to the design of experimental facilities. ASC simulations were used to design an optimized collimator system for the DARHT hydrodynamic testing facility that significantly increased the resolution of this facility.

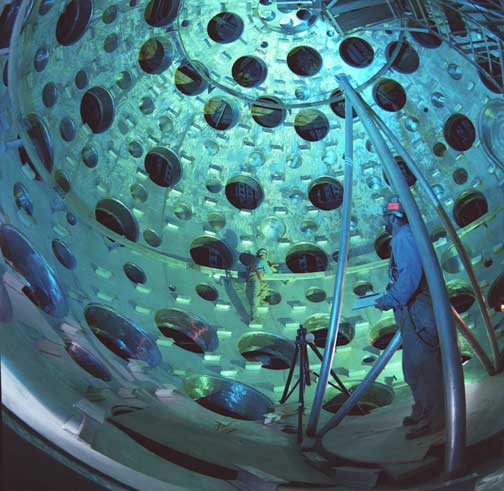

Future facilities such as the Advanced Hydrodynamic facility, and the National Ignition Facility (NIF) will provide validation data for ASC simulation capabilities. The advanced hydrodynamic capability will provide multiple spatial views at various times in the implosion phase of a primary. These experimental data will be used to validate the predictive capability of primary implosions.

The NIF will provide data regarding thermonuclear ignition and burn of deuterium-tritium (see Fig. 10). Data for primary certification includes ignition capsule test bed for boost studies, instability growth in solid state, and high strain effects on implosion. Data for secondary certification includes radiation transport, hydrodynamic effects at high energy densities, and material properties. For further details, please visit the NIF Web site.

UCRL-MI-125923

April 16, 2002