OFFICE OF ADVANCED SIMULATION AND COMPUTING AND INSTITUTIONAL R&D PROGRAMS (NA-114)

Quarterly Highlights | Volume 4, Issue 4 | November 2021

In This Issue

LANL validation of nuclear data using physical uncertainty bounds, machine learning.

LANL tools optimize manufacturing workflows.

LLNL modernization of nuclear data, processing codes improves accuracy.

LANL achieves more realistic material modeling in national security simulations.

Sandia discovers the hidden culprit killing lithium-metal batteries from the inside.

LDRD investigators drive innovation to the threshold of fusion ignition.

ASC & LDRD Community—Upcoming Events (at time of publication)

- Supercomputing 2021, St. Louis, MO (with hybrid virtual sessions); November 14–19

- AI @ DOE Workshop Part 1 - December 8-9, 2021; Part 2 - January 12-13, 2022

- Predictive Engineering Science Panel (PESP) meeting at SNL-CA; January 24-28, 2022

- Exascale Computing Project IPR; March 15-17, 2022

- Predictive Science Panel (PSP) Meeting at LANL; March 21-25, 2022

- ECP “All Hands” Meeting in Kansas City, MO; May 2-5, 2022

- ASC Principal Investigators Meeting, Monterey Hyatt/Naval Post Graduate School in Monterey, CA; May 16-19, 2022

Questions? Comments? Contact Us.

Welcome to the fourth 2021 issue of the NA-114 newsletter - published quarterly to socialize the impactful work being performed by the NNSA laboratories and our other partners. This issue begins with a highlight from the Lawrence Livermore National Laboratory (LLNL) in which researchers are using mesoscale simulations performed on the Sierra supercomputer to better understand the influence of manufacturing defects on material microstructures for a range of experimental loading conditions (like the copper crystal orientations shown in the banner above). Also highlighted in this issue is Los Alamos National Laboratory’s (LANL’s) efforts applying machine learning techniques to the validation of nuclear data libraries, essential for reliable simulations and a proper understanding of uncertainties in predictions supporting stockpile stewardship. Other highlights include:

- LANL tools to help the NNSA production complex optimize workflows and accelerate manufacturing while still preserving fidelity in component/part inspections.

- LLNL modernization of nuclear data through its toolkit “For Updating Data and Generating Evaluations” (“FUDGE”).

- Contributions of ASC-funded codes (LASNEX, ARES, and MARBL) that have supported the Inertial Confinement Fusion (ICF) Program and provided key insights to the groundbreaking August 8th 1.3 megajoule experiment at the National Ignition Facility (NIF).

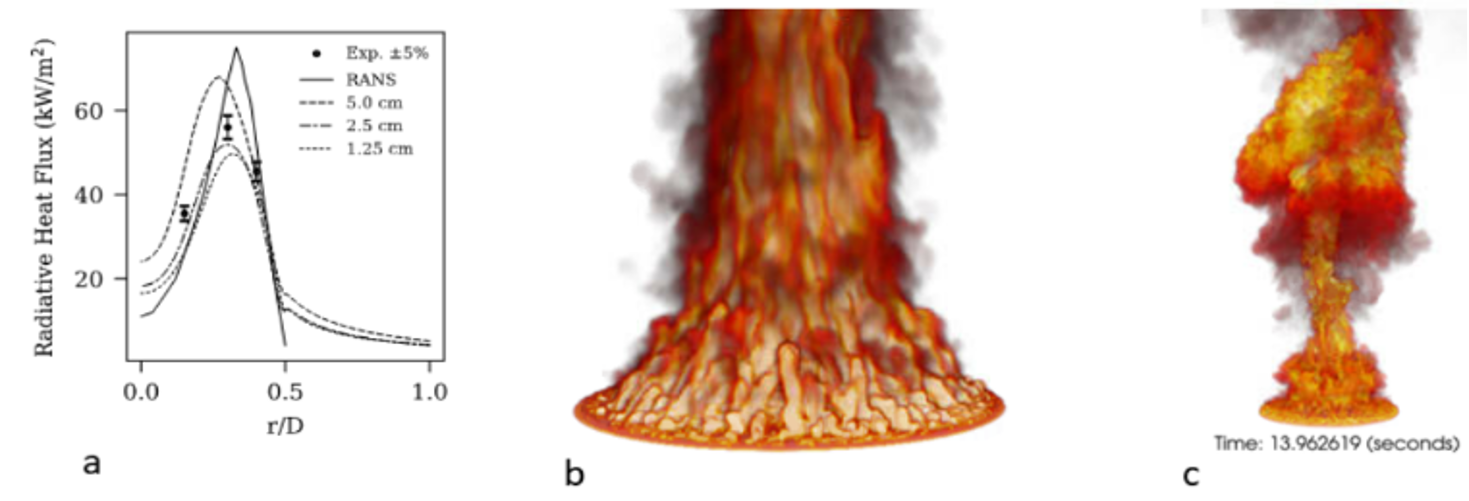

- Sandia National Laboratories’ (SNL) state-of-the-art fire physics model suite that supports modeling in nuclear deterrence transportation accident scenarios (simulation results for a five-meter pool fire are shown at the right).

Please join me in congratulating the dedicated professionals who delivered the achievements highlighted in this newsletter, in support of our national security mission.

Thuc Hoang

NA-114 Office Director

LLNL team uses mesoscale simulation to explain dynamic behavior of manufacturing defects observed in focused experiments.

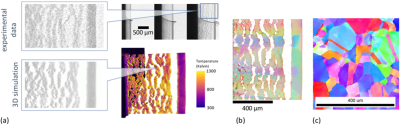

Understanding manufacturing defects is important to stockpile stewardship for efficient production, particularly for part acceptance rates. Correspondingly, we are interested in the response of surface scratches and other defects under dynamic loading conditions. At facilities such as the Dynamic Compression Sector (DCS) that provide more detailed observations, experimentally accessible conditions are limited; hence simulations are being used to understand the transferability of experimental observations to a wider set of conditions. Recent experiments on copper at DCS showed jet formation and breakup features that could not be explained by simulations employing traditional macroscale material models. In the case highlighted here, a visible surface scratch 215 micrometers wide (roughly two times the width of a human hair) produces a planar jet under impact loading, and the jet breakup is imaged using x-rays. With crystalline grains in the copper having the same size scale as the scratch, only a few grains contribute material to a given portion of the jet. As shown in Figure 1(a), simulations that include the microstructure capture the nature of the jet breakup. Specifics of which crystals flow into the jet influence the nature of the breakup, and Figure 1(b) depicts the crystal orientations in the simulated jet. Initial orientations are sampled from those measured in the copper (Figure 1(c)). These results provide an explanation for the variability seen in the experiments, and insights into the expected influence of manufacturing defects across a wider range of conditions.

The calculations were conducted using the ASC ALE3D finite element code and the Sierra system. The graphics processing unit (GPU)-based Sierra computing architecture allows for rapid throughput of these 3D calculations, enabling exploration across a range of experimental loading conditions and for varying material microstructure. The simulation shown in Figure 1, with more than 300 million elements, ran on 40 nodes (160 Nvidia V100 GPUs) in less than twelve hours. (LLNL-ABS-828853)

LANL performs validation of nuclear data using physical uncertainty bounds and machine learning.

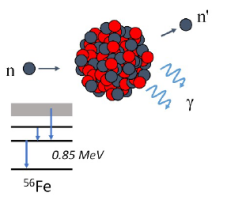

Nuclear data tabulate our knowledge of particle interactions with an atom’s nucleus, such as a neutron interacting with a 239Pu nucleus. Neutron transport codes at LANL rely on vast data libraries covering the chart of nuclides to answer questions for stockpile stewardship, neutron dosimetry, neutron criticality safety, and many other applications. Validation of nuclear data libraries is essential to ensuring reliable simulations and a proper understanding of uncertainties in our predictions.

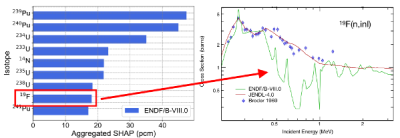

Machine learning methods are being applied to validate thousands of nuclear data mean values with hundreds of small-scale experiments. This is a difficult task for traditional validation techniques because of the complex relationships between high-dimensional data. Machine learning methods have correctly identified known shortcomings in our nuclear data libraries and have also found previously overlooked issues (see Figure 2 for an example). This work has culminated in the EUCLID project (in the LDRD-Directed Research portfolio) that aims at finding critical issues in nuclear data and resolving them by designing and executing dedicated small-scale experiments.

Additionally, the Physical Uncertainty Bounds (PUBs) method was used for the first time to assess more realistic uncertainties and bounds on important evaluated nuclear data. Ongoing work will deliver uncertainties to stakeholders that can be easily used in codes and forward-propagated to assess bounds on predictions for complex systems. As part of the international Cross Section Evaluation Working Group (CSEWG), automated testing of the reliability of nuclear data uncertainties based on PUBs has recently begun. (LA-UR-21-27003)

LANL enables manufacturing through tools to optimize manufacturing workflows.

Coordinate Measuring Machines (CMM) have been widely used at LANL in the 3D inspection of hemi-shells. Contour inspections are conducted by rotating the part in 0.75° increments azimuthally and by 2° increments in the polar direction. This provides a very dense array of data points at the pole and increasingly sparse data points at the equator. This inspection strategy is a historical carry over from Century Detroit gauging machine usage at Rocky Flats.

A reduced number of inspection locations would decrease the inspection time and reduce the likelihood of introducing defects during the interaction between the probe and hemi-shell. To determine if the number of inspection points can be reduced, LANL is characterizing the typical defects observed during production of legacy hemi-shells. LANL’s goal is to find the balance that satisfies an optimally reduced number of inspection locations while maintaining the ability to detect small surface defects and out-of-spec conditions.

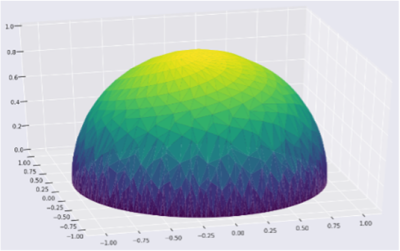

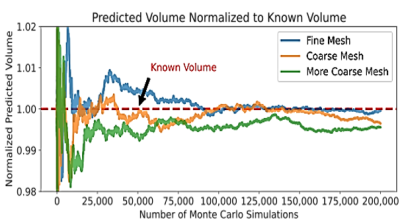

The team developed three different mathematical approaches with increasing complexity, accuracy, and run time. These methods evaluate the volume of a theoretical hemi-shell mesh created from a varying number of datapoints (per polar angle) and compared it to the real part volume. Figure 3 shows one approach that uses Monte Carlo simulation to estimate the volume of a meshed hemi-shell using ray casting and the Möller-Trumbore algorithm. Here, LANL evaluated the predicted volume while varying azimuthal scan degrees to characterize the meshed object at different mesh fidelities. As can be seen, the results approach a value as more points are simulated. The code was parallelized and is used to the desired accuracy for the inspection process. Tools like these will help the production complex to make decisions about accelerating manufacturing while still preserving fidelity in part inspections. (LA-UR-21-27754)

LLNL modernization of nuclear data and processing codes improves data accuracy.

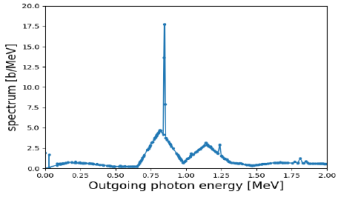

Nuclear data are essential for a wide range of applications including stockpile stewardship, astrophysics, nuclear medicine, criticality safety, and nuclear energy. The Nuclear Data and Theory (NDT) group at LLNL uses a variety of codes to test, process, and deliver nuclear data to the user base across these fields. An important part of the NDT’s suite of codes is the FUDGE toolkit. FUDGE (For Updating Data and Generating Evaluations) is written using modern software practices and an object-oriented structure supports a variety of workflows. FUDGE is the world leader in supporting the new Generalized Nuclear Data Structure (GNDS) format, which is more flexible and extensive than legacy formats, improving the representation of nuclear data. After FUDGE processing, GNDS files can be loaded and used in radiation transport applications with the help of a new C++ library also developed by the NDT group. Simulations with benchmark models using the LLNL transport codes Mercury (Monte Carlo) and Ardra (deterministic) are already showing improved results using GNDS data compared to legacy LLNL data. For example, outgoing particle distributions are better represented and sampled, and photonuclear data can now be used in the transport codes. FUDGE has also been used to verify the data in the library. LLNL recently identified issues with the representation of gammas from neutron inelastic scatter reactions, notably from high-lying continuum states, as shown in Figures 4 and 5. For some isotopes, gamma emissions from these states are incorrectly denoted by broad triangular or rectangular distributions. FUDGE tools were used to identify the issue and demonstrate the problem to the broader nuclear data community, where active efforts are underway to correct the data. (LLNL-ABS-828857)

NA-114/ASC-funded codes, infrastructure, and tools, plus NA-113/OES-funded code HYDRA, provided key insights supporting LLNL’s August 8th experiment at NIF.

HYDRA is the main ICF computational tool that is funded by NA-113, but ASC funds codes such as LASNEX, ARES, and MARBL that also contribute to the overall ICF Program and provided some key insights to the August 8th groundbreaking experiment atNIF. Thenon-localthermodynamic equilibrium opacity model used in HYDRA, which is critical for accuracy of the radiation drive, was partly developed and ported to graphics processing units (GPUs) with ASC funds. HYDRA also relies on other ASC products, such as HYPRE as its linear solver library and Visit for visualization, and received some support from the ASC- funded El Capitan Center of Excellence. Additionally, the El Capitan Splash application code that ASC is funding will have HYDRA at its core and includes artificial intelligence-enabled physical models, mesh management (also funded out of ASC), and design optimization loops. As part of the LLNL Weapon Simulation & Computing (WSC) Program, the HYDRA project benefits from much of the infrastructure and tools LLNL has built with ASC funds. (LLNL-ABS-828865)

Sandia establishes credibility for a state-of-the-art fire physics model suite supporting modeling in nuclear deterrence transportation accident scenarios.

Credibility of a large-eddy simulation (LES) generalized heat loss and flamelet-based model suite for pool fire simulations has been established in SIERRA/Fuego code. Researchers at Sandia deployed a formal validation study for an outdoor five-meter pool fire in quiescent conditions. The study exercised Sandia’s recent unstructured numerical techniques along with advanced turbulence, combustion, and soot models. The LES model is coupled to the SIERRA-based participating media radiation solver. Exciting fire dynamics phenomena such as fingering and puffing are now accurately captured (see Figure 6). This work represents an effort spanning three ASC portfolios: V&V, P&EM, and IC, and was recently published in Physics of Fluids as an Editor’s Pick (see https://doi.org/10.1063/5.0060267). The novel capability will be used to establish realistic ranges for radiative heat flux and other quantities of interest in and around fires. The fire physics model suite is expected to be deployed for production fire analysis in FY22 and support transportation accident scenarios of interest to nuclear deterrence. (SAND2021-10318 O)

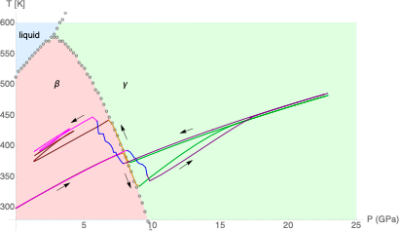

LANL achieves more realistic material modeling in national security simulations.

As simulation codes become increasingly capable there is a demand for more realistic materials models. For example, there is a desire to use different strength models depending on phase. It is obvious that using the same strength model for a liquid and a solid phase is not a realistic modeling approach for most materials. LANL has recently focused on being able to take into account the phase of the materials using a multiphase framework. To be able to use these new models in hydrocodes, the teams must advance the parts of the codes that use these models.

In Figure 7, the path in phase space of a specific Lagrangian cell in a ramp-driven tin rod simulation is shown. This figure shows results both for a simple, flattened multiphase table (with tabulated equilibrium mass fractions of the different phases), and also for a new advanced treatment with a separate equation of state (EOS) for each phase and a kinetic phase transition model (See Figure 7 (1)). The kinetic model takes into account that a real phase transition is not immediate, but the material needs some time to rearrange its ions into the new phase.

A well-known example of a kinetic phase transition is super-cooled water. Even though the environment in a raindrop can become so cold that the water should be frozen, the freezing process does not start until nucleation happens. If there is no impurity present in the rain drop where nucleation can start, the freezing occurs only when the system is severely disturbed by landing on the asphalt. Another important, but much more complicated kinetic phase transition that we are far from being able to model is the one used when producing steels. The cooling rate from the austenite phase decides the kinetics of the phase transition and results in different micro-structured steels ranging from martensite to pearlite, with many different bainite structures in between.

This effort was made possible through a broad collaboration between simulation code developers and equation of state experts. Kinetic phase transition models have not been available before in LANL’s core hydrocodes, nor have separate phase tables and tabulated equilibrium mass fractions been used. LANL expects this new capability to more realistically model phase transitions and to advance our ability to take micro-structural influences on materials properties into account. (LA-UR-21-27003)

A new LLNL ASC atomic-scale model sets the stage for strength capabilities accounting for manufacturing impurity effects in plutonium.

Multi-scale modeling has long provided a path to predictive constitutive models, and over the last two years, LLNL’s Physics and Engineering Models (PEM) subprogram has advanced new approaches based on the use of ASC capability-class computing resources. As reported in previous ASC program milestones, these advances have focused on pure plutonium. Here LLNL reports on work that sets the stage for using the new approach to address alloying, aging, and impurity effects on material response. While these factors are known to influence the strength of plutonium at ambient quasi-static conditions, a predictive model based on atomic-scale behavior has not heretofore been available. With the significant relevance of impurities to manufacturing cost and throughput, work in this area has been prioritized and LLNL has constructed a new interatomic potential that treats alloying and impurity effects. Following this approach, the simulations do not need to specify in advance what mechanism causes changes in the material response – instead LLNL will be conducting simulations at various impurity levels and quantifying the results that emerge. Development of the potential is a key step in evaluating manufacturing impurity effects. In future work LLNL will examine the port of the new potential to run on GPUs, as that port would enable evaluation over a wider range of conditions using capability-class computing resources. For additional details, contact the ASC HQ Program Office. (LLNL-ABS-829001)

Engineers at Sandia have added a translation capability to the Xyce Circuit Simulator that enables faster turnaround time for radiation effects analysis of various weapon system integrated circuits.

In the design and simulation of analog/mixed signal (AMS) circuits, netlists (a list of the electronic components in a circuit and the way they are connected) produced by commercial tools for analog simulators come in many dialects. With the latest release of Sandia’s Xyce analog circuit simulator, the XDM translator has added the capability of translating Spectre netlists. Spectre is the simulator for Cadence Virtuoso, one of the primary industry tools used in the design of integrated circuits (ICs), including many ICs designed at Sandia for weapon systems and other applications. Early adopters of the translation capability have found the netlist translation to be faster and less error prone, as it eliminates many intermediate steps. In addition, it enables the simulation of radiation effects in large circuits using Xyce for netlists that could not be translated using other methods. (SAND2021-8685 O)

Through LDRD, Sandia discovers the hidden culprit killing lithium-metal batteries from the inside.

For decades, scientists have tried to make reliable lithium-metal batteries. These high-performance storage cells hold 50% more energy than their prolific, lithium-ion cousins, but higher failure rates and safety problems like fires and explosions have crippled commercialization efforts.

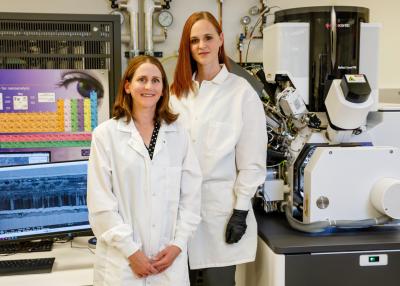

Now, the first nanoscale images ever taken inside intact, lithium-metal coin batteries (also called button cells or watch batteries) challenge prevailing theories and could help make future high-performance batteries, such as for electric vehicles, safer, more powerful and longer lasting.

“We’re learning we should be using separator materials tuned for lithium metal,” said battery scientist Katie Harrison, who leads Sandia’s team for improving the performance of the batteries.

Through LDRD funding, Harrison’s team found a surprising second culprit: a hard buildup formed as a byproduct of the battery’s internal chemical reactions. Every time the battery recharged, the byproduct, called solid electrolyte interphase, grew. Capping the lithium, it tore holes in the separator, creating openings for metal deposits to spread and form a short. Together, the lithium deposits and the byproduct were much more destructive than previously believed, acting less like a needle and more like a snowplow. “The separator is completely shredded,” Harrison said, adding that this mechanism has only been observed under fast charging rates needed for electric vehicle technologies, but not slower rates.

Determining cause-of-death for a coin battery is difficult because of its stainless-steel casing. The metal shell limits what diagnostics, like X-rays, can see from the outside, while removing parts of the cell for analysis rips apart the battery’s layers and distorts whatever evidence might be inside. Katie Jungjohann, a Sandia nanoscale imaging scientist at the Center for Integrated Technologies, and her collaborators used a microscope with a laser to mill through a battery’s outer casing. They paired it with a sample holder that keeps the cell’s liquid electrolyte frozen at temperatures between -148 and -184 degrees Fahrenheit (-100 and -120 degrees Celsius, respectively). The laser creates an opening just large enough for a narrow electron beam to enter and bounce back onto a detector, delivering a high-resolution image of the battery’s internal cross section with enough detail to distinguish the different materials.

The original demonstration instrument, the only such tool in the United States at the time, now resides at a Thermo Fisher Scientific laboratory in Oregon. An updated duplicate tool at Sandia will be used to help solve many materials and failure-analysis problems. “This is what battery researchers have always wanted to see,” Jungjohann said. (SAND2021-7265E)

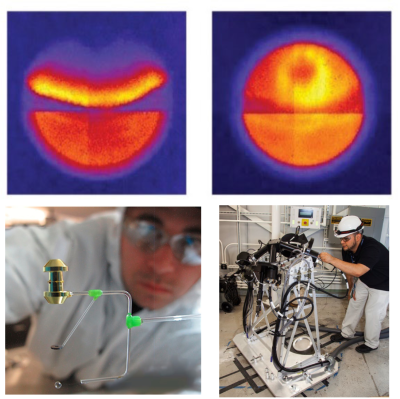

LDRD investigators drive innovation to the threshold of fusion ignition.

During August 2021, an experiment conducted at LLNL’s NIF made a significant step in the decades-long quest of inertial confinement fusion—attaining a yield of more than 1.3 megajoules. The ability to focus the energy from 192 high-power laser beams at NIF onto a tiny fuel capsule that is typically only a few millimeters in size, and then create a reaction that generates more than 10 quadrillion watts of power, puts researchers at the threshold of fusion ignition.

The ground-breaking experiment did not happen overnight. It was the result of many innovations, developed in recent decades by pioneering scientists and engineers at NNSA national laboratories, working in collaboration with colleagues at other DOE/NNSA sites and other research institutions. Those innovations came together to culminate in the recent high-yield fusion experiment at NIF.

Many of those pioneering new ideas were transformed into solutions through funding provided by LDRD Programs at the NNSA laboratories (a few examples are shown in Figure 8). LDRD investments in this foundational work over the last two decades spanned key science and technology areas, including target fabrication, diagnostic tools, and laser-plasma interactions. Read more about this foundational work online in the NNSA LDRD FY21 Fourth Quarter Highlights. (LLNL-MI-827281)

Questions? Comments? Contact Us.

NA-114 Office Director: Thuc Hoang, 202-586-7050

- Integrated Codes: Jim Peltz, 202-586-7564

- Physics and Engineering Models/LDRD: Anthony Lewis, 202-287-6367

- Verification and Validation: David Etim, 202-586-8081

- Computational Systems and Software Environment: Si Hammond, 202-586-5748

- Facility Operations and User Support: K. Mike Lang, 301-903-0240

- Advanced Technology Development and Mitigation: Thuc Hoang